Emission

Plastics can release undesirable, irritating, or toxic chemical compounds. For this reason, automotive manufacturers have begun to regulate the type and quantity of emissions. In the regulations for automotive suppliers, various tests are prescribed, depending on the respective Original Equipment Manufacturer (OEM), which must be carried out under precisely defined conditions.

Emissions – Causes and Effects

Plastics can release undesirable, irritating, or even toxic chemical compounds. Some emissions can lead to discomfort or health damage in high concentrations. Other emissions, however, represent ‘merely’ an odor nuisance. Therefore, automotive manufacturers have begun to regulate the type and quantity of emissions. In the regulations for automotive suppliers, depending on the OEM, odor tests, fogging tests, and emission measurements are prescribed, which must be carried out under precisely defined conditions.

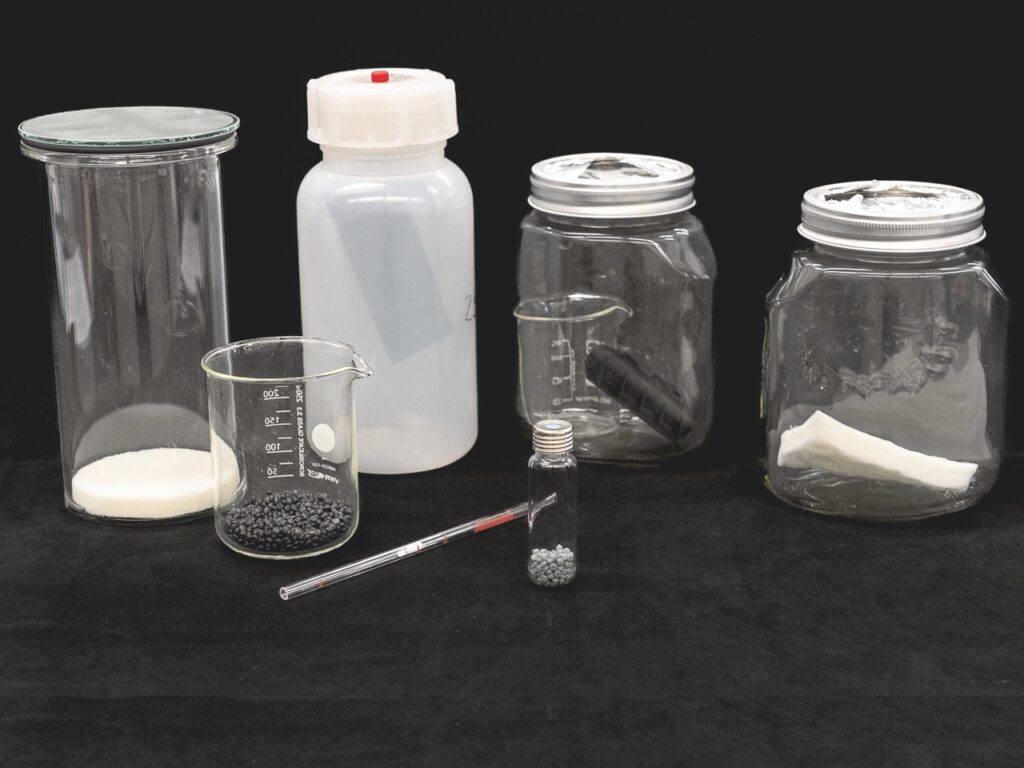

Odor Testing

In an odor test, the odor of a material is determined by a trained test panel and evaluated with grades. According to VDA 270, the scale for odor testing ranges from grade 1 “not perceptible” to grade 6 “intolerable” (e.g., VW/Audi, Saab Volvo). However, depending on the OEM’s specification, there may also be different evaluation scales for odor testing (e.g., from 0 to 5 or -3 to +3).

Fogging Test

Fogging refers to the outgassing of individual material components that then condense in the component’s environment. In a car, for example, fogging can lead to a greasy film on the windshield. The condensable components of the part can be measured by a gravimetric (DIN 75201-B) or reflectometric (DIN 75201-A) fogging test. For this purpose, the sample is heated. The volatile components escape from the component and condense in the (colder) component environment. In the gravimetric fogging test, the weight increase due to condensation is measured. The determined value is given in mg and typically lies in the range of less than 5 or 2 mg. In the reflectometric fogging test, the reflection of the surface with the film is determined and given as a percentage, and should therefore be as high as possible. A good reflectometer value is in the range of > 80%.

Emission Testing

An emission test serves to determine the concentration of undesirable or even harmful substances in a component. For example, the mass-related formaldehyde value of a material can be measured using the flask method (VDA 275). Formaldehyde is a pungent-smelling gas that not only irritates the eyes and respiratory tract but is also classified as “possibly carcinogenic”. Due to its widespread use as a starting product, e.g., for dyes or synthetic resins, formaldehyde determination is among the frequently requested emission measurements. The determination of the total carbon emission of a sample is also possible within the scope of emission testing (VDA 277). The static headspace GC/FID method is suitable for the simultaneous determination of easily and moderately volatile compounds, but not for the detection of highly volatile components. The total carbon emission is given in µg C/g (micrograms of carbon per gram).

While only the total amount of carbon emission is measured within the scope of VDA 277, combining thermodesorption and GC/MS (VDA 278) makes it possible to identify volatile (VOC) and condensable (FOG) emissions more precisely. A detailed table with qualitative and quantitative individual results, including the evaluation of individual critical substances, is obtained.