Polymer Characterization

Analysis of Plastics

Plastics are ubiquitous: in cars, packaging, household appliances, medical products, and electronics. However, not all plastics are the same – polymers behave very differently depending on their composition and processing. Therefore, it is crucial to know their properties precisely.

The Polymer Characterization helps to test, compare, optimize materials, or identify sources of error. Analytik Service Obernburg (ASO) offers a wide range of testing methods – clearly structured into four key areas:

1. Chemical Polymer Characterization

What is done?

We analyze the chemical composition of plastics – specifically: Which polymers are present? Which additives (e.g., plasticizers, stabilizers) are included? Are there residues or impurities (e.g., residual monomer)?

Typical Methods:

- IR/Raman Spectroscopy

- NMR Spectroscopy (400 MHz)

- Soxhlet Extraction (according to DIN EN ISO 6427)

- Emission Tests (Fogging, Odor, GC/MS)

- Determination of Ignition Residue (DIN EN ISO 3451-1)

- Elemental Analysis (ICP-OES, XRF)

Why is this important?

The chemical composition determines how a plastic behaves – for example, when exposed to heat, in contact with chemicals, or during long-term use. In cases of complaints or material failure, chemical analysis often provides crucial insights.

For whom?

- Manufacturers and processors of plastics

- Companies that want to test raw materials

- Quality and damage analysis, e..g., in medical technology or the automotive industry

2. Physicochemical and Thermal Polymer Characterization

What is done?

We analyze the physicochemical and thermal properties of plastics. These include, among others, the molecular weight, the chain length distribution, the crystallinity as well as the thermal behavior – for example, melting and decomposition points or brittleness at low temperatures.

Typical Methods:

- Gel Permeation Chromatography (GPC/SEC)

- Solution Viscosity

- NMR Spectroscopy (Diffusion Behavior)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

Why is this important?

These properties significantly influence processing (e..g., injection molding), mechanical properties (stiffness, toughness), heat resistance or transparency of plastics. Even minor changes in structure can have significant effects on the final product – for example, regarding temperature resistance, sterilizability or long-term stability.

For whom?

- Developers of technical plastic components

- Manufacturers with high quality standards

- Clients from the electronics, packaging, aerospace, medical, and household appliance industries

What is done?

We analyze the physicochemical and thermal properties of plastics. These include, among others, the molecular weight, the chain length distribution, the crystallinity as well as the thermal behavior – for example, melting and decomposition points or brittleness at low temperatures.

Typical Methods:

- Gel Permeation Chromatography (GPC/SEC)

- Solution Viscosity

- NMR Spectroscopy (Diffusion Behavior)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

Why is this important?

These properties significantly influence processing (e..g., injection molding), mechanical properties (stiffness, toughness), heat resistance or transparency of plastics. Even minor changes in structure can have significant effects on the final product – for example, regarding temperature resistance, sterilizability or long-term stability.

For whom?

- Developers of technical plastic components

- Manufacturers with high quality standards

- Clients from the electronics, packaging, aerospace, medical, and household appliance industries

3. Mechanical Polymer Characterization

What is done?

We test the resilience of a plastic – for example, how much tensile force it can withstand or how much it deforms before breaking. For this purpose, we also produce test specimens from granulates according to DIN EN ISO 527.

Typical Methods:

- Tensile Test (according to DIN EN ISO 527)

- Hardness Testing

- Impact Strength

Why is this important?

Mechanical properties are crucial for a product’s safety and lifespan. Especially for load-bearing or moving parts, it is essential that the plastic functions reliably.

For whom?

- Designers in the automotive and mechanical engineering industries

- Developers of durable components for medical devices or packaging solutions

- Testing Institutes & QA Departments

Application Examples

Solution Viscosity

Solution Viscosity of Polyamides according to DIN EN ISO 307, of Polyester and other Polymers according to DIN EN ISO 1628-2, -5 and ISO 1628-4

Objective

Do you want to know the influence of your processes on polymer properties or optimize your processing steps? Are you interested in whether a material tends to degrade under certain environmental influences? Do you want to check the polymer properties of your granulate and thus your suppliers’ compliance with specifications?

Solution

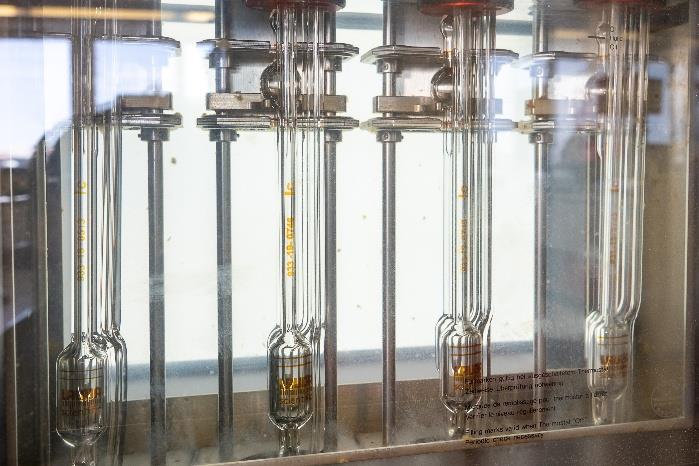

The viscosity number provides information related to the chain length of macromolecules. The procedure (Fig. 1) is standardized for common plastics:

- DIN EN ISO 307 for Polyamides

- DIN EN ISO 1628-2, -5 and ISO 1628-4 for Polyester and other polymers such as polycarbonate and polybutylene terephthalate.

Analytik Service Obernburg has decades of experience and high expertise in this field, which is also demonstrated by excellent interlaboratory test results.

- Industries: Automotive suppliers, chemical fibers, plastics processors

- Analysis Objectives: Optimization, quality assurance, damage analysis

- Materials: Fibers, plastic granulates, injection molded parts

- Analysis Methods: DIN EN ISO 307, DIN EN ISO 1628-2, -5 and ISO 1628-4

- Related Questions: Plastics analysis, viscosity measurements

Appropriate sample preparation is a very important part of this service.

Through a high degree of automation (Fig. 2), we are able to produce polymer solutions for measurement with great precision.

We offer viscosity number determination in a variety of solvents.

Our standard repertoire includes:

- Formic acid

- m-Cresol

- Dichloroacetic acid

- Sulfuric acid

- Hexafluoroisopropanol

- Chloroform

- Tetrachloroethane

- Solvent mixtures such as:

- Phenol / 1,1,2,2-Tetrachloroethane

- Phenol / 1,2-Dichlorobenzene

Do you require the viscosity number in a different solvent or solvent mixture?

Do not hesitate – simply contact us.

Advantages

Our qualified employees work in this analysis area around the clock (24/7).

This allows us to react quickly even in very urgent cases. Results within 24 hours are possible with us.

Contact us – we will find the best solution.

You focus on your processes, we handle the necessary analyses.

Fig. 1: Fully automatic solution viscosity measurement system; enables rapid processing of large sample series.

Fig. 2: Automated sample preparation system; typical polymer concentrations are 0.005 g/cm³ (0.5%) and 0.01 g/cm³ (1%).

Recycling of Plastic Windows

Heavy Metal Detection with ICP-OES – Recycling of Plastic Window Profiles

Objective

For decades, PVC plastic windows have been used in the construction sector, which, however – unlike today’s windows – contain certain amounts of lead and cadmium as additives. The PVC from old window frames could, in principle, be well recycled and reused in significant proportions in new window frames, were it not for the problem with unwanted heavy metals.

Solution

There are methods to extract heavy metals from shredded old window material. The task of Analytik Service Obernburg is the regular verification that this has been successfully achieved. For this purpose, a portion of the recyclate is chemically digested. The heavy metal contents in the corresponding solution are quantified using inductively coupled plasma emission spectroscopy (ICP-OES). From this, it can be deduced at what concentration the regranulate can be added to the process without exceeding limit values. Similarly, due to the high detection sensitivity of the method, it is possible to characterize sections of a new window frame with recyclate admixture regarding traces of heavy metals.

Industries & Applications

- Construction Industry

- Plastics Processors

- Plastics Recyclers

Analysis Objectives

- Quality Assurance

Materials

- PVC Regranulate

Analysis Methods

- ICP-OES (Inductively Coupled Plasma Emission Spectroscopy)

Advantages

Abrasion and wear testing devices make it possible to investigate the wear of technical textiles in the laboratory. Additionally, by simultaneously exposing them to media, their influence on abrasion and wear behavior can be simulated in fast motion. Based on the results of these tests, the suitability and quality of materials can be assessed.

Fig 1: Detection of heavy metals using ICP-OES

Core co-extruded window profile section Layer co-extruded window profile section

Particle Size Analysis

Particle Analysis – Characterization of Powders and Suspensions

Objective

The processing properties of a powder or suspension critically depend on the particle size, particle shape, and surface chemistry of the particles. Thus, one powder may flow finely, while another tends to clump. Particles that are too large can clog filters, while particles that are too small can cause significant dust formation during further processing. This is just a small selection of issues attributable to different particle properties.

Solution

At Analytik Service Obernburg, various analytical methods are used for particle characterization, which will be discussed in more detail below.

Industries & Applications

- Medical Technology

- Paint Manufacturers

- Compounders

Analysis Objectives

- Particle Size

- Particle Shape

- Agglomeration Tendency

Materials

- Powders

- Suspensions

Analysis Methods

- Laser Diffraction

- Scanning Electron Microscopy (SEM-EDX)

Example – Particle Size Distribution

The particle size distribution is determined using laser diffraction. Particles between 0.1 μm and 2000 μm can be measured. A distribution curve is obtained, from which the particle size can be read, as well as various statistical values describing the distribution. These values can be directly used for validating the manufacturing process in quality assurance. The test is performed on the powder dispersed in water. By measuring with and without ultrasound, a distinction can be made between agglomerates and primary particles.

Example – Particle Shape

Various microscopic measurement methods are available for investigating particle shape – from light microscopy to electron microscopy (SEM) and atomic force microscopy (AFM). These methods allow characterization not only of the particle’s morphology but also its surface microstructure. Both are crucial for the interaction between particles (e.g., agglomeration tendency). If required, the particle’s morphology can be quantified by subsequent computer image analysis.

Example – Surface Chemistry

Just like particle morphology, surface chemistry (moisture, foreign substances such as oils, or targeted surface modifications) also influences the properties during processing or the distribution of particles in the final product. Depending on the question, different chemical or spectroscopic methods are used here to detect changes in surface chemistry.

Advantages

The described methods allow for comprehensive characterization and visualization of particles in powders or suspensions. This enables the analysis of raw materials or products within the scope of quality assurance. The methods are also suitable for determining the cause of problems (e.g., during processing) in case of damage. Furthermore, Analytik Service Obernburg possesses extensive expertise for the analysis of catalysts or fillers in solids.

Fig. 1: Particle size distribution of two samples from different production batches.

Fig. 2: Comparison of powders with different agglomeration tendencies

Our Experts